-

SANDBLASTING

-

Abrasives, Media, Grit

-

Anchor Blasting Pattern

Abrasive sizes vary and a tolerance of 10% should be maintained to expect these results, especially where abrasives are reclaimed and re-used. Reclaimed abrasives should be angular, not rounded and free from oil, grease, iron oxide, etc.

Anchor Pattern

Anchor Pattern | The anchor pattern or profile is extremely important to protective coatings in that it provides for excellent coating adhesion. Coatings manufacturers specify the optimal profile needed to achieve maximum coating adhesion for each different coating.

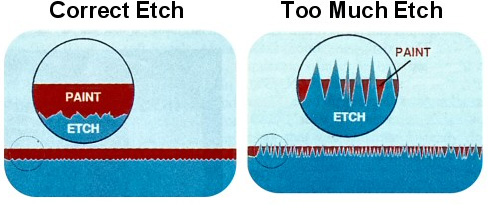

Anchor pattern can be thought of as tiny peaks and valleys in the substrate being blasted. The depth of these “valley’s” is determined by the size, type and hardiness of the abrasive being used; by the air pressure; and by the distance and angle of the nozzle to the surface. Too much anchor pattern wastes coating and allows substrate to show through; too little anchor pattern reduces the bonding surface between the material and the substrate.

Typically anchor pattern is expressed in mils, microns or millimeter

• 1mil = 1/1,000 in.

• 25 microns = 1 ml

• 25.4 millimeters = 1 in.

• 39 mils = millimeter

Pressure, distance from the surface and angle can effect the anchor pattern but following are some general guidelines on how to achieve specific anchor patterns. Assumption is 90PSI nozzle pressure, 2 feet from surface:

| ANCHOR PATTERN | BLAST MEDIA |

|---|---|

| .5 Mil | 120/150 Jetmag, 100 garnet, 120 aluminum oxide |

| 1 Mil | 35-70 Jetmag, 80 garnet, 100 aluminum oxide, 80 steel grit |

| 1.5 Mils | 35-70 Jetmag, 36 garnet, 36 aluminum oxide, 50 steel grit |

| 2 Mils | 32-B4 Jetmag, 36 garnet, 36 aluminum oxide, 40 steel grit |

| 2.5 Mil | 30-60 Jetmag,36 garnet, 24 aluminum oxide, 25 steel grit |

| 3 Mils | 30-60 Jetmag, 16 garnet, 16 aluminum oxide, 16 steel grit |

About JH Norton Company, Inc.

(formerly, Norton Sandblasting Equipment)

JH Norton Company, Inc. is a premier stocking distributor for the leading manufacturers of surface preparation, dust collection, and industrial vacuum equipment and product lines. We are also leaders in the industry for newer technologies such as Sponge Blasting, Automation. Robotics and Laser Ablation technologies. Be sure to visit our Facebook page.

Norton Sandblasting Equipment is now JH Norton Company, Inc.

Dedicated to meeting your blasting and surface preparation needs with quality equipment, parts and supplies since 1973