-

OTHER EQUIPMENT

-

Dry Air

-

Schmidt® AxxiomAirPrep™ Aftercooler and Air Dryer Systems

Compressed air entering the AirPrep system passes through a prefilter, removing severe contaminates, particles, and moisture before going to the cooler. The air then enters the lower tank where it expands and slows down, allowing the moisture to fall out. Next, air travels up through a stainless steel particle filter or deliquescent tablets into the clean air manifold. The air is now cooler, cleaner and drier, with very little drop in pressure

Aftercooler System ACS 250™

Note: Sizes other than the 250 are skid mounted

Contact Norton Sandblasting Equipment for pricing and experienced assistance in determining which aftercooler or air dryer system is right for your portable baster.

Why Control Moisture?

Moisture in your compressed air is a big problem! It makes the abrasive in your blast machine damp or wet, causing the abrasive flow from the machine to be uneven and reduce or even completely block media flow. The operator may find himself opening the media valve to get more grit, thus wasting the grit. Moist abrasive media can adhere to the internal components of the blaster, and when it dries, it can be extremely difficult to remove! Water and oil vapors can cause “flash rusting” on the surface of steel products and oil vapors deposited on surfaces will cause paint and other coatings to adhere poorly or create early failures such as chipping and separating.

Schmidt® Axxiom Moisture Separators

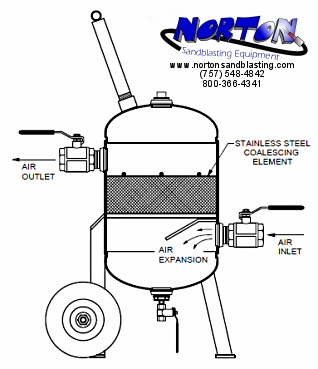

Moisture accumulates in compressed air in vapor form at the air compressor. The moisture creates problems when the hot compressed air is cooled and the vapor condenses into water droplets. In blast systems, this cooling occurs in two primary areas. First, when the air enters the blast pot where it expands. Second, as the compressed air exits the blast nozzle and again it expands. The expansion cools the air causing condensation of moisture in the blast media and on the object being blasted. The Schmidt moisture separator allows the air to expand inside an ASME coded pressure vessel where moisture condenses and is trapped by the stainless steel coalescing element.

Norton Sandblasting Equipment is now JH Norton Company, Inc.

Dedicated to meeting your blasting and surface preparation needs with quality equipment, parts and supplies since 1973