-

OTHER EQUIPMENT

-

Power Tools

-

MBX™ Surface Treatment System

MBX ADVANTAGES

- Faster, more effective

- For hard-to-reach areas (e.g. 90 degree angles)

- Creates sandblasted finish of smooth surface

- No heat/ no toxic fumes

- Saves time and money

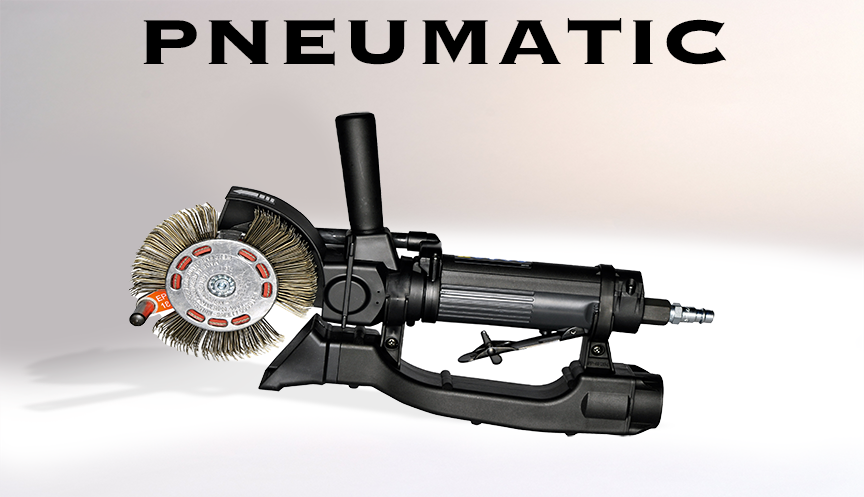

MBX™ Metal Blaster

FAQ MBX Metal BlasterThe MBX™ Metal Blaster is a patented surface treatment system. The MBX Metal Blaster System consists of a pneumatic or electric power tool and replaceable wire brush belts (coarse, medium, fine, and stainless steel) and rubber eraser wheels (vinyl zapper). Once the MBX Belt is in motion, centrifugal force causes the belt to tighten and runsmoothly and gently as if suspended on a cushion of air. This makes it possible to easily and safely process corners, sharp edges, difficult contours and even welding seams.