-

OTHER EQUIPMENT

-

Power Tools

-

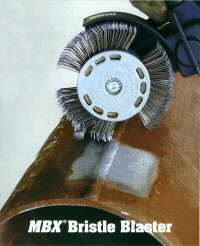

MBX™ Bristle Blaster

MBX™ Bristle Blaster by Monti

Part Number Electric: MT-USSE-06-02

Part Number Pneumatic: MT-USSP-06-02

The bristle blasting process is a new innovation that both removes corrosion and generates an anchor profile (also known as “anchor pattern”) by using a specially designed rotary bristle tool. This tool consists of hardened wire bristle tips that are bent forward and dynamically tuned to a hand-held power tool which operates at approximately 3,500 rpm. The bristle tips are designed to strike the corroded surface with kinetic energy. Immediately after the bristle tips strike the corroded steel surface, they retract from the surface, which results in both corrosion removal and a micro-indentation that exposes fresh metal surface.

Common Applications

- removal of corrosion, mill scale, protective coatings

- post-weld cleaning

- well-drilling and bridge refurbishment

- fabrication and repair of naval / marine vessels

- industrial maintenance

Key Features of the Bristle Blasting Process…

- Corrosion/Coating Removal

- meets SSPC “white metal” visual standards

- Improved fatigue resistance

- due to compressive residual stress generated at the surface

- Surface texture/profile

- anchor pattern 2.5 to 3.5 mils

- Increased surface hardness

- for improved wear resistance

- Simplicity

- eliminates the need for complex abrasive blast equipment

Note: The MBX Bristle Blaster Set includes a carry case. Always wear protective equipment such as gloves and face/eye protection. Additional protective measures may be required, dependent upon your specific situation, laws, and policies.

Be sure to visit our Norton Sandblasting Equipment on Facebook.

Also, see Buy sandblasting equipment, parts, and accessories online.